Apparel

Aruj Apparel Division is a state of the art purpose built facility which is SEDEX APPROVED and BSCI COMPLIANT, capable of producing 200,000 units per month. Aruj Apparel Division is one of the fastest growing company specialising in manufacturing of fashion garments (Non-Denim and Denim). Currently we are supplying goods to a long list of satisfied customers based in UK, Europe and USA.

Aruj Apparel Division has highly qualified and technically trained staff and workforce which are working as a closely knitted family based on corporate culture, values and beliefs. Our team is capable of taking on challenges for fulfilling every work related task with dynamism and dedicated efforts. Aruj Apparel Division is socially responsible company complying with all labour laws of Pakistan.

We have diversified product line and are committed to deliver the right product in right time to our valuable customers and believes in a long term partnership with customers by means of standing right by its customers in time of needs.

- Pre Stitching

Fabric Inspection

Fabric Inspection Department check following properties of the fabric and carry out test before handing the fabric to the production department.

• Fabric Roll Inspection is done

• Fabric is checked for Spinning and Weaving grading accordingly

• Skew Test is carried out

• Width of the fabric is Measured

• GSM is checked

• Shrinkage Test is carried outGerber Garment Technology (GGT)

The method of manual pattern making was a lengthy and time-consuming process, however with the vast popularity of GGT the process of pattern making is now an easy and reliable process. Grading of garments can be done with the availability of just one base size. At Aruj Industries Limited all advance systems are incorporated and we use state-of-the-art Gerber technology, along with digitizer and plotter, which ensures precision in all patterns we produce. The GGT Department is responsible for the following tasks.

• Base Pattern Making

• Production Pattern Making

• Marker Making

• Plotting of Marker

• Marker Inspection

• Forward the Final Approved Pattern to Cutting DepartmentCutting

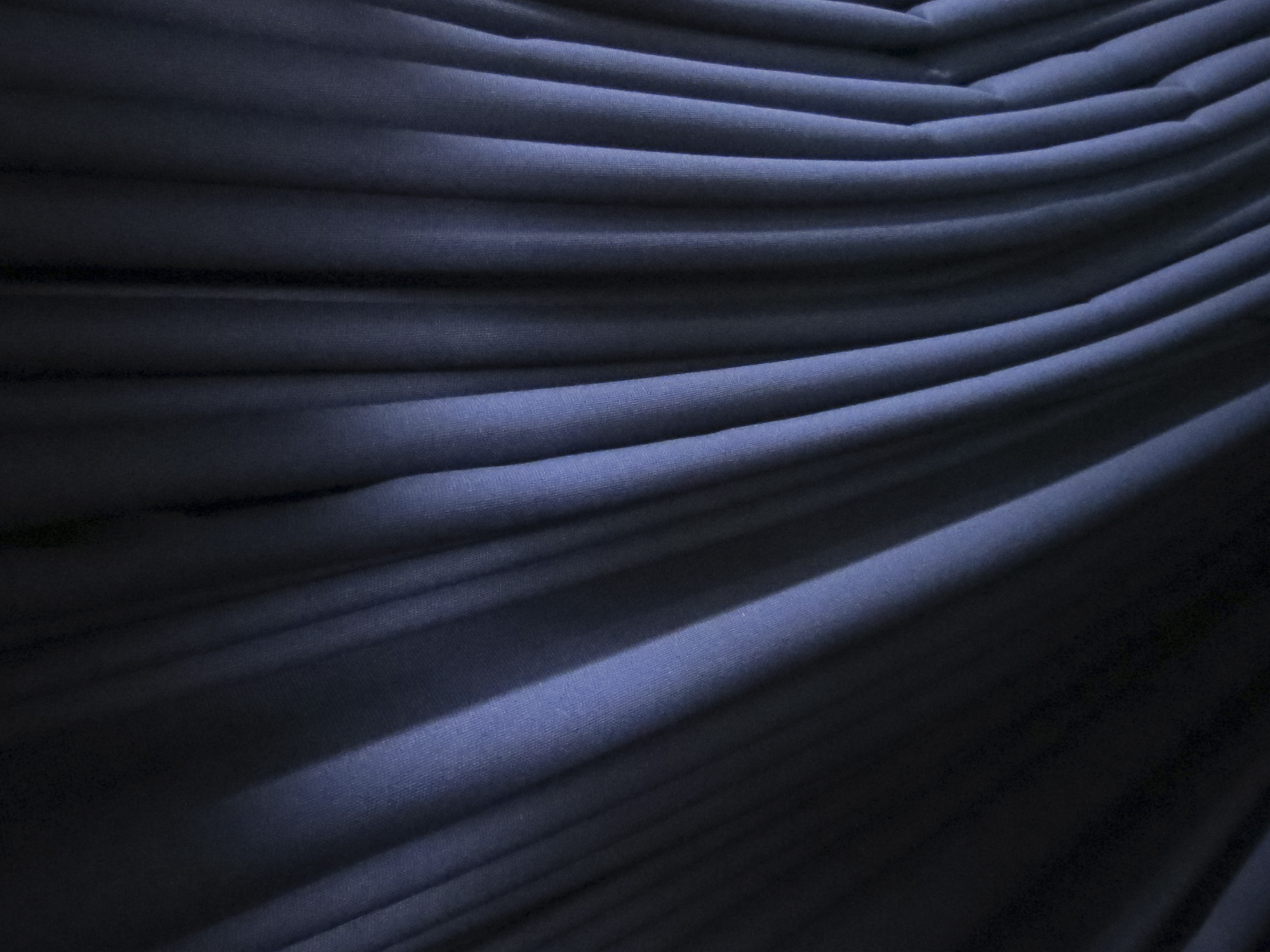

Garment production starts with the cutting process. After receiving the approved pattern the fabric is cut into components. The fabric is cut marked and verified with precision ensuring 100% quality of all the components.

• Fabric is sorted according to its Shrinkage and Shade

• Fabric is allowed to Relax for a few hours

• Fabric is placed on the cutting tables

• Marker paper is placed on the Lay

• Fabric Cutting is carried out

• Numbering is done on the cut fabric

• 100% checking of parts and replaced if needed

• Sorting and Bundling is done

• Hand over to WIPCD- Stitching Process

Work In Process Control Department (WIPCD)

Work in Process Control Department (WIPCD) is an integral part of any garment unit. WIPCD is responsible for all work in progress from cut to pack, looking after smooth flow of an order from department to department. WIPCD covers an order Quantity, Quality and follow all processes of garment making. All orders record is maintained by WIPCD.

• Controlling all work in process on daily basis

• Order wise daily reporting and recording from cutting to packing

• Garments receiving and issuance from department to department

• Taking care of garment shortages, and leftovers

• To ensure complete and timely delivery of ordersStitching Process

Stitching Department is where the garment takes its shape. This department is divided into 4 major sections i-e Small Parts, Front Section, Back Section and Assembly

• Small Parts are stitched according to stitching standard with inline quality check and compared with the standard

• Front panel are stitched separately so is the Back panel both undergoing inline quality checks

• After Small parts, Front panel and Back Panel are stitched they are handed over to Assembly Section

• In the Assembly Section the garment is assembled quality check is done and is handed over to WIPCDQuality Before Wash

- Post Stitching

Washing

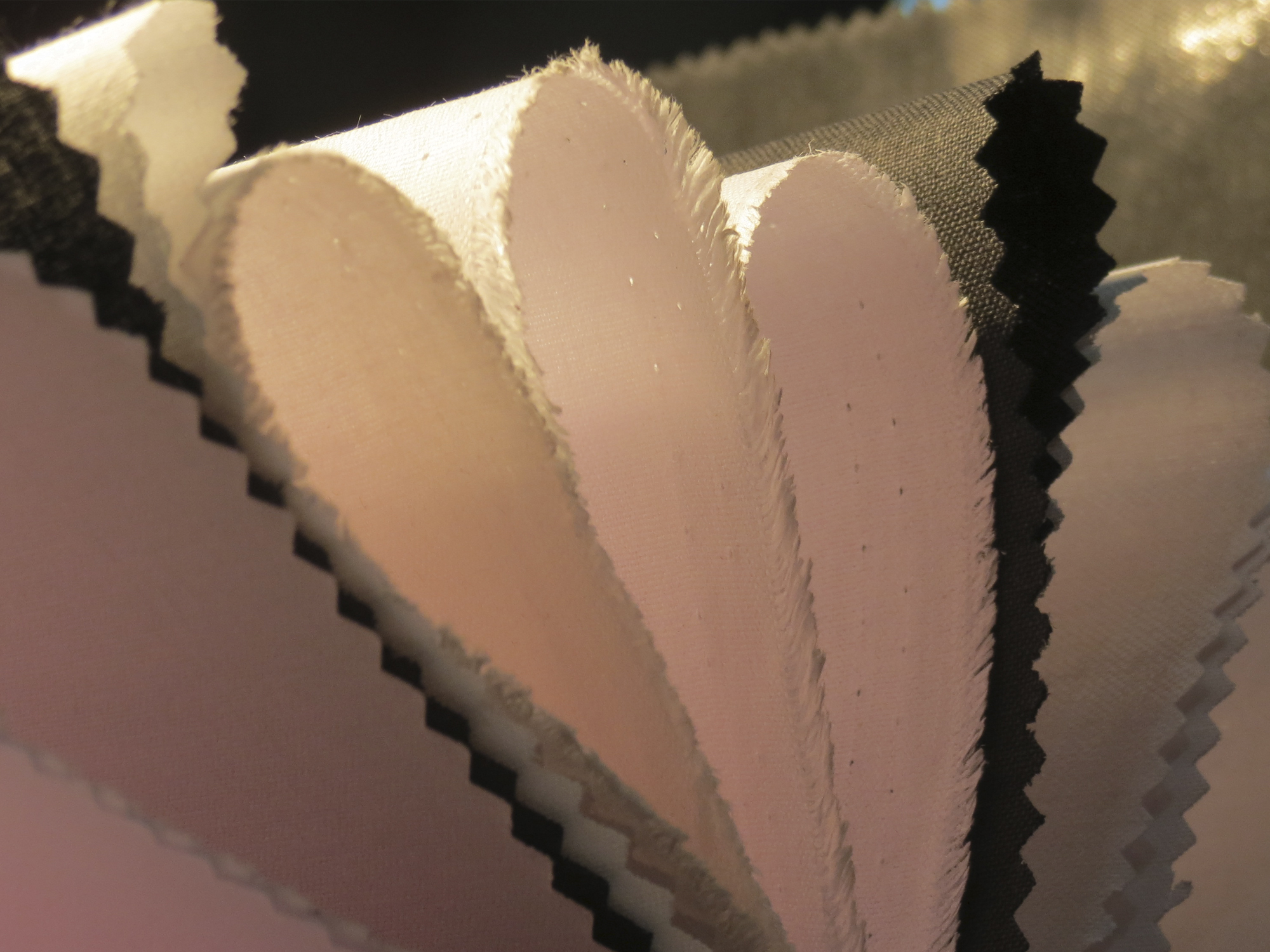

Aruj Industries Limited specializes in the use of traditional dry processes such as grinding, hand scraping and chemical sprays. Washing department is divided into two sections: Dry process and Wet process. Washing is done with great care to achieve the required look, feel and quality

• First Bundle is Washed

• Quality of the first bundle is checked

• Washing Approval is given on the basis of the result of first bundle wash

• Dry Process as per approved sample is carried out (IF REQUIRED)

• First Bulk Wash is done

• Bulk is Dried and again checked for quality

• Dry process Spraying is done after the bulk is dried

• Final Effects if any are applied

• Final Wash is carried out

• Quality is once again checked before finalizing the order

• After all approvals and meeting all the requirements the order is handed over to WIPCDButton Rivet

After the Washing Process is complete Buttoning and Riveting is carried out on the garments. All buttons and rivets are placed with great care so that there is no loose button or rivet on any garment in the order.

Trimming

Trimming is carried out with state of the art machines and manually to make sure there is no loose threads on the garment.

Pressing

After all the garments are trimmed they are forwarded to Pressing Department for Pressing.

Pressing is done with great care.Measurment

After Buttoning, Trimming and Ironing the garments are Measured and checked as per the specs provided by the customer.

- Finishing Process

Finishing

Final Inspection

Quality A-W

- Packing Process

Packing

Quality Assurance

Dispatch