Quality

Our Quality team is involved in every stage of Interlining, Dyeing and Finishing processes from greige fabric to finish product. Quality Department has been especially set up to ensure thorough inspection at every stage. The quality control Department is backed up by a fully equipped Lab that scrutinises and checks the processed fabrics and every stage to insure customer specification are continually met and surpassed.

- Greige Fabric Testing

Greige Inspection

We check the following properties of fabric before taking into production according to the customer’s specs. supplied.

➢ GSM of fabric (ISO 3801)

➢ Fabric construction (ASTM D / ISO 4407)

➢ Width of fabric (ASTM D 1059 / ISO 1773)

➢ Yarn Fiber Identification /Blend Ratio (ISO 4407)

➢ Sizing Identification and size %age

If any above specs. in not according to customer’s given spec. the fabric is rejected and informed to customer through Marketing.Greige Stitching

Greige stitching is done very carefully by checking the following parameters.

➢ Face and Back of every piece.

➢ Tear by hand to get parallel of weft yarn of both pieces to stitch

➢ Must be ensured that there is no puckering after stitch.

➢ Both side of every stich is forth locked by single needle machine.- Pre Treatment Testing

Singe Desize

The Quality team checks the following parameters of machine.

➢ Brushing Roller must be at even pressure and air suction throughout the width.

➢ Randomly nip test of padder to ensure chemical padding.

➢ Wrap of fabric on A Frame with polythene sheets.

➢ After wrap rotation of fabric on rotation stand at speed 4-6 RPM

➢ Ensure equal dwelling time of each A Frame of same job.Scour Bleach

Scour Bleach of fabric is tested by checking the following parameters

➢ Check the pre washing and post washing temp of steam. It should be near to boil i.e. 85-90 OC.

➢ Check the dwelling time and temp of steamer according to given recipe which should be 95-100 OC.

➢ Check the concentration of Caustic Soda/ H2O2 applied on fabric by titration after every 30 min.

➢ Following tests are performed before further process after every about 2000 mtr

• Width of fabric (ISO 1773)

• Residual Size %age (By Tegewa Scale)

• Absorbency Test of fabric ( By Capillary Test DIN 53924)

• Absorbency Test of fabric (By Drop Test method)

• Whiteness of Fabric CIE Method by Spectrophotometer

• pH of Fabric (ISO 1413)

• Skew %age after Garment Wash (ISO-BS-2819)Mercerize

➢ Concentration of Caustic Lye by OBe meter of mercerizing and recovery zone of machine.

➢ Width of fabric before and after mercerizing (ISO 1773)

➢ Shrinkage %age of fabric after mercerizing by Test method ISO 6330

➢ Barium activity no. to evaluate degree of mercerizing (AATCC 89 )

➢ pH of fabric (ISO 1413)- Dyed Fabric Testing

Dyeing

Dyeing

➢ Color combination selection at the time of Lab. Dipping process keeping in view washing fastness, Light fastness, Chlorine fastness etc. according to the customer requirements.

➢ Shade matching verification , Shade continuity and LCR by taking width

➢ Color fastness to washing after Dye/Wash of each trolly/Frame. (Test method ISO CO6 / AATCC-61)

➢ If fastness results are okay then okay for finishing process.- Finished Fabric Testing

Finishing

FINISHING

➢ Dimensional stability of Warp and Weft is measured after finish and then after sanforizing Process.

➢ Before packing following tests are performed according to customer requirements.

➢ GSM ISO 3801

➢ Shade Matching CIE, CMC method Spectrophotometer method

➢ Width of Fabric EN ISO 1773

➢ Dimensional Stability (ISO 6330)

➢ Skew %age BS ISO 2819

➢ Colorfastness to washing ISO 105 CO6

➢ Rubbing Dry and Wet ISO 105 X12

➢ Colorfastness to Perspiration ISO 105 EO1

➢ Colorfastness to Hypochlorite ISO 105 NO1

➢ Color Fastness to Hydrogen per Oxide ISO 105 NO2

➢ Colorfastness to Dry Clean ISO 105 DO1

➢ Color fastness to Light ISO 105 BO2

➢ Formaldehyde Contents ISO 1484-1

➢ Blending Ratio ISO 4407

➢ pH of fabric ISO 1413

➢ Pilling Resistance ISO 12945-2 @ 5000 cycle

➢ Abrasion resistance ISO 12945-2 25000 cycle

➢ Tensile Strength ISO 13934-1

➢ Tear Strength ISO 13937-1

➢ Flame retardant BS 5438- 10 Sec

➢ Water repellant AATCC 22

➢ Smoothness appearance after

➢ Domestic Home Laundry AATCC 124- Packed Fabric Testing

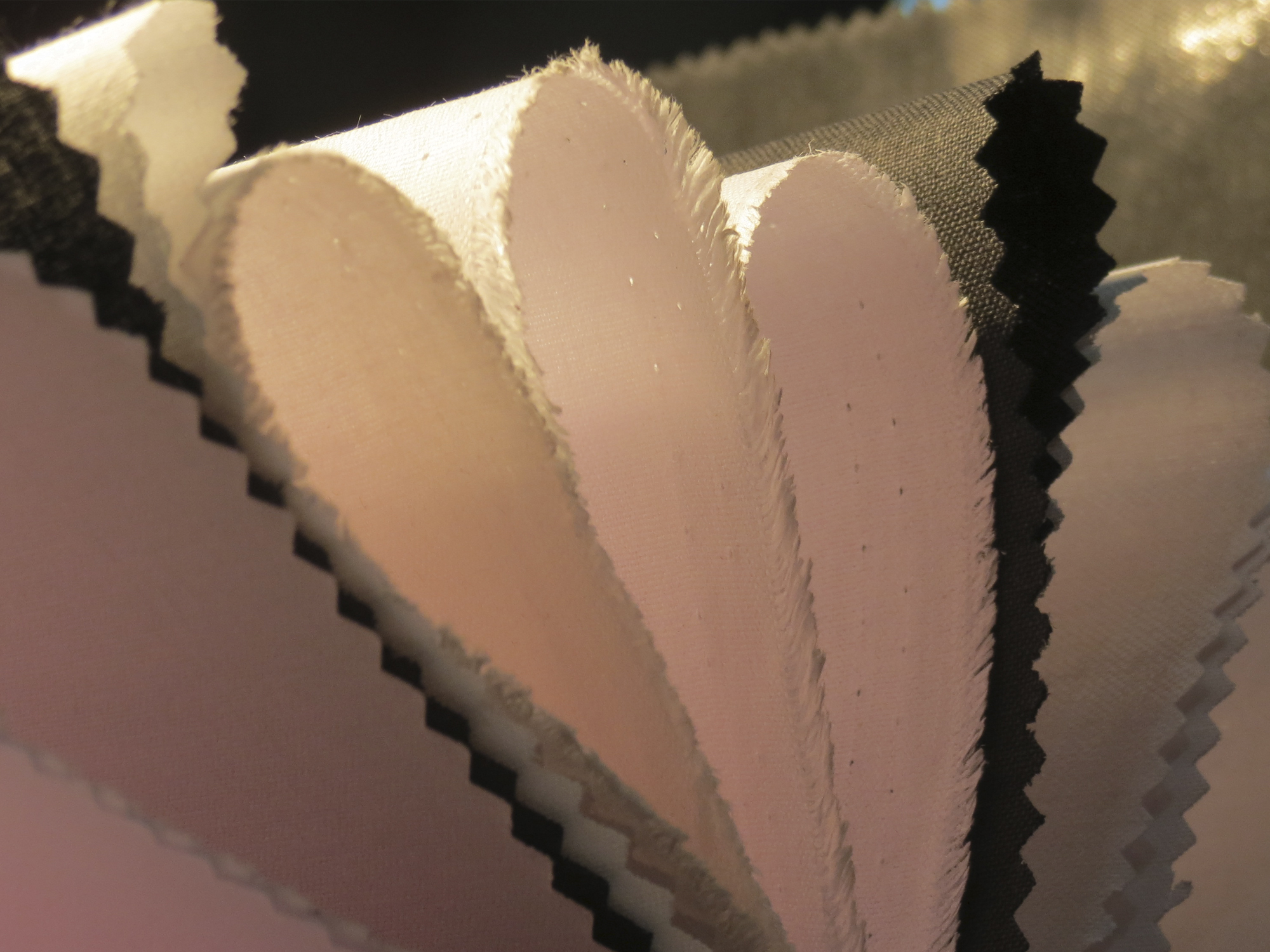

Packing

➢ All and every meter of fabric is inspected on inspection frame according to the international 4 Points system

➢ Minimum and maximum piece length according to customer spec.

➢ Three samples of 10-12 inch length of each piece is taken as head Ends one for the customer and one for the Lab record.- Laboratory Instruments

List of Equipment